A full-service precision machine shop providing parts and components of the highest quality for aerospace, automotive, and motorsports applications.

Global Air Capabilities: Deep Expertise and State-of-the-Art Equipment

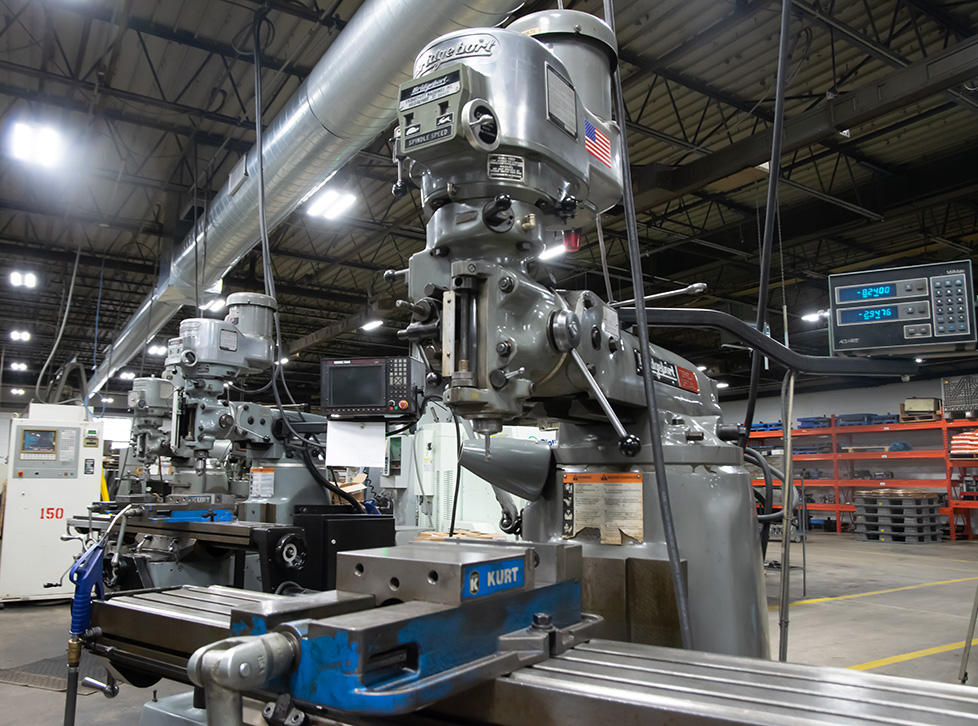

Conventional Machining

- CNC Milling

- CNC Lathe Turning

- Grinding

- Lapping

- Drilling and Boring

Non Conventional Machining

- CNC Water Jet Machining

- CNC Laser Cutting

- Wire EDM

Assembly

- Brazing

- MIG and TIG Welding

Additional Capabilities

- Advanced Part Marking Technologies Available

- Toolmaking

- Plastic Injection Molding

When Quality and Precision are Paramount, Global Air Delivers

Certified for Quality Outcomes on Every Project

AS9100 Certified

The aerospace industry standards in AS9100 focus on risk management and specific measures to document meeting requirements conformance and on-time delivery performance.

ISO9001 Certified

The quality management systems we’ve implemented, along with our demonstrated commitment to continual improvement, has fulfilled the requirements of the ISO9001 standards.

Rolls Royce Approved

These standards go even further than either ISO9001 or AS9100 in meeting the highest industry standards for quality parts and components when the application demands it.

The Global Air Difference: High-Quality Parts and Components

Whether its turbine engine components used in the aerospace industry (both defense and commercial), precision transmission parts that keep the nation’s commercial-duty vehicles moving, or high-performance parts for the motorsports industry, each of these applications demand the highest quality and precision possible, and Global Air delivers.